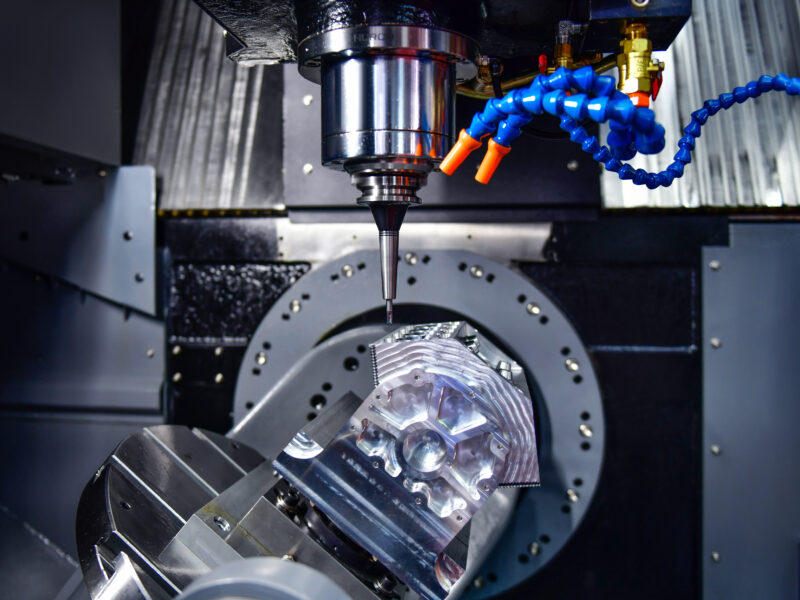

CNC machining remains one of the most precise and versatile manufacturing methods for working with metal.

Among the wide array of materials available, certain metals are preferred for their strength, machinability, corrosion resistance, and application-specific advantages.

Whether you’re manufacturing aerospace parts, medical implants, or industrial tooling, understanding the properties and applications of these metals helps optimize both performance and cost. This article explores the top five metals used in CNC machining and where they are most effectively applied.

1. Aluminum – Lightweight and Highly Machinable

Why Aluminum?

Aluminum is one of the most widely used metals in CNC machining due to its excellent machinability, strength-to-weight ratio, and corrosion resistance. It’s easy to mill, drill, and turn, which makes it ideal for high-speed CNC operations.

Common Grades:

-

6061-T6 – General-purpose alloy used in most structural parts

-

7075-T6 – High-strength grade often used in aerospace

-

2024 – Aircraft-grade aluminum with excellent fatigue resistance

Key Properties:

-

Lightweight

-

Excellent thermal conductivity

-

Anodizing compatibility

-

Cost-effective for prototyping and production

Common Applications:

| Industry | Components |

|---|---|

| Aerospace | Wing ribs, brackets, fuselage components |

| Automotive | Housings, engine mounts, suspension parts |

| Consumer Goods | Electronics enclosures, bicycle parts |

| Robotics | Structural frames, sensor housings |

Aluminum remains the top choice where strength, low weight, and affordability must align.

2. Stainless Steel – Strength and Corrosion Resistance

Why Stainless Steel?

Stainless steel is known for its exceptional corrosion resistance, hardness, and strength under stress. It’s suitable for CNC machining across a wide range of industries, especially when hygiene, durability, or temperature resistance is required.

Common Grades:

-

304 – General-purpose stainless steel with good weldability

-

316 – Marine and medical grade, with superior corrosion resistance

-

17-4 PH – Precipitation-hardened alloy for high-strength, high-fatigue resistance parts

Key Properties:

-

Corrosion and oxidation resistance

-

High tensile strength

-

Long service life

-

Maintains integrity in extreme environments

Common Applications:

| Industry | Components |

|---|---|

| Medical | Surgical tools, orthopedic implants |

| Food Processing | Blades, nozzles, pumps, mixers |

| Oil & Gas | Valves, flanges, sensor housings |

| Industrial | Fasteners, shafts, gears, and high-load parts |

Due to its sanitary finish and resilience, stainless steel is essential in high-wear or critical systems.

3. Titanium – Biocompatible and High Strength-to-Weight Ratio

Why Titanium?

Titanium is known for its unmatched combination of strength, light weight, and biocompatibility. Although more challenging to machine than aluminum or steel, its properties make it indispensable in demanding applications.

Common Grades:

-

Grade 2 – Commercially pure titanium, used for moderate strength applications

-

Grade 5 (Ti-6Al-4V) – Aerospace and medical industry standard for strength and fatigue resistance

Key Properties:

-

Exceptional corrosion resistance

-

Low density and high strength

-

Biocompatible and non-toxic

-

Excellent fatigue resistance

Common Applications:

| Industry | Components |

|---|---|

| Aerospace | Jet engine parts, airframe structures |

| Medical | Dental implants, orthopedic screws/plates |

| Marine | Propeller shafts, heat exchangers |

| Defense | Armor plating, guided missile components |

When weight savings and durability matter—especially in critical or life-supporting systems—titanium leads.

4. Brass – Easy to Machine with High Electrical Conductivity

Why Brass?

Brass is an alloy of copper and zinc that is easy to machine and has a low coefficient of friction. It’s ideal for components requiring low wear, smooth finishes, or good electrical conductivity.

Common Grades:

-

C360 (Free-Cutting Brass) – Excellent for precision CNC work

-

C260 (Cartridge Brass) – More corrosion-resistant, used in fluid systems

Key Properties:

-

Excellent machinability (ideal for high-speed turning)

-

Naturally corrosion-resistant

-

Smooth surface finish and low friction

-

Good electrical and thermal conductivity

Common Applications:

| Industry | Components |

|---|---|

| Electronics | Terminals, contacts, connectors |

| Plumbing | Fittings, valves, manifolds |

| Medical | Low-friction movement joints and adapters |

| Automotive | Decorative trims, sensor contacts |

Brass is a go-to choice where aesthetic finish, electrical performance, or fluid sealing are essential.

5. Copper – Superior Thermal and Electrical Conductor

Why Copper?

Copper is highly valued in CNC machining for its exceptional conductivity and antimicrobial properties. It’s more difficult to machine than brass or aluminum due to its softness and tendency to adhere to cutting tools, but with the right tooling, it yields excellent results.

Common Grades:

-

C110 (Electrolytic Tough Pitch Copper) – Highly conductive, used in electronics

-

C145 (Tellurium Copper) – Better machinability for precision CNC parts

Key Properties:

-

Top-tier electrical and thermal conductivity

-

Antimicrobial properties

-

High ductility

-

Resistant to corrosion in moist environments

Common Applications:

| Industry | Components |

|---|---|

| Electronics | Busbars, heat sinks, connectors |

| HVAC | Heat exchangers, tubing, coils |

| Medical | High-purity contact surfaces and terminals |

| Renewable Energy | Solar panel components, battery connectors |

Copper is unmatched where heat or electricity needs to move efficiently across the component.

Choosing the Right Metal for CNC Machining Projects

Each of these metals offers distinct advantages depending on application, cost, and performance needs.

While aluminum remains the most versatile and budget-friendly, stainless steel and titanium dominate in medical and aerospace use cases. Brass and copper fill the niche for electrical and aesthetic components.

Before selecting a material, consider:

-

Final part function (load-bearing, thermal, aesthetic?)

-

Required surface finish

-

Strength and corrosion resistance

-

Machining speed and tool wear

-

Tolerance and complexity

Working with a capable CNC provider ensures the right balance of material, machining strategy, and cost efficiency. In some cases, comparing subtractive CNC with additive methods also helps determine the most efficient path forward—especially in early prototyping.

You can explore both CNC and additive processes together by checking available 3D printing technologies that complement metal machining.

Summary: Top 5 Metals in CNC Machining

| Metal | Strengths | Primary Use Cases |

|---|---|---|

| Aluminum | Lightweight, fast to machine | Aerospace, electronics, consumer goods |

| Stainless Steel | Durable, corrosion-resistant | Medical, food, industrial machinery |

| Titanium | Strong, biocompatible, fatigue-resistant | Medical implants, aerospace components |

| Brass | Easy to machine, low friction, conductive | Connectors, plumbing, mechanical parts |

| Copper | Best electrical/thermal conductivity | Electronics, HVAC, medical contacts |

Final Thoughts

Selecting the right metal for CNC machining is about more than cost—it’s about performance, precision, and reliability.

Each of the metals above brings a unique value to the manufacturing process, depending on your industry and product requirements.

Whether you’re machining a one-off aerospace bracket, a custom medical implant, or a high-volume electronic component, choosing the correct metal ensures your design functions as intended—and lasts as expected.