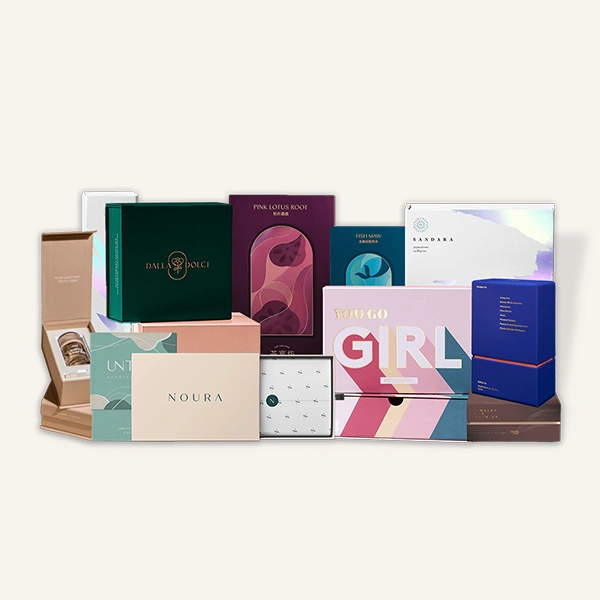

In today’s competitive market, packaging plays a crucial role in brand perception and product protection. A Rigid Box Maker specializes in crafting high-end, durable boxes that enhance the luxury appeal of various products. Whether for electronics, cosmetics, jewelry, or high-end fashion accessories, rigid boxes provide a premium unboxing experience and strong structural integrity.

Additionally, a Corrugated Cardboard Manufacturer produces durable, eco-friendly materials that complement rigid box production, ensuring maximum protection and sustainability. In this article, we will explore the role of a Rigid Box Maker, the benefits of rigid boxes, and how they compare with Corrugated Cardboard Manufacturer in terms of production, materials, and applications.

Understanding Rigid Boxes

Rigid boxes, also known as set top boxes, are non-collapsible packaging solutions typically made from thick paperboard wrapped in decorative materials. Unlike folding cartons, rigid boxes maintain their shape and structure, making them ideal for luxury and high-value products.

1. Materials Used by a Rigid Box Maker

A Rigid Box Maker carefully selects high-quality materials to ensure durability, aesthetics, and functionality. Common materials include:

- Greyboard (Chipboard): The primary material used for rigidity and strength.

- Art Paper & Specialty Paper: Used for wrapping and enhancing visual appeal.

- Foil & Laminates: Provide an extra touch of elegance and durability.

- Corrugated Inserts: Often provided by a Corrugated Cardboard Manufacturer for added protection.

2. Types of Rigid Boxes

- Magnetic Closure Boxes: Feature built-in magnets for a seamless opening and closing experience.

- Drawer Style Boxes: Provide a slide-out feature for easy access to the product.

- Lift-off Lid Boxes: Simple yet elegant, commonly used for luxury packaging.

- Collapsible Rigid Boxes: Maintain durability while allowing easy storage and transportation.

- Hinged Lid Boxes: Offer a premium feel with a book-like opening design.

Benefits of Working with a Rigid Box Maker

Choosing an experienced Rigid Box Maker ensures superior quality, exceptional design, and enhanced brand value. Here’s why rigid boxes are a preferred choice for premium packaging:

1. Premium Aesthetic Appeal

- Enhances brand image with high-quality finishes.

- Offers a luxurious unboxing experience.

- Provides extensive customization options.

2. Strong & Durable Protection

- Rigid boxes are made from thick materials, preventing damage to fragile products.

- A Corrugated Cardboard Manufacturer can supply inserts to improve shock resistance.

- Ideal for storing and shipping valuable or delicate items.

3. Custom Branding & Unique Design

- Advanced printing techniques like embossing, debossing, and foil stamping make rigid boxes visually appealing.

- Custom sizes, shapes, and finishes align with a brand’s image and product requirements.

- Ideal for limited-edition and gift packaging solutions.

4. Eco-Friendly & Sustainable Packaging

- Many Rigid Box Makers focus on recyclable materials.

- Collaboration with a Corrugated Cardboard Manufacturer ensures sustainable packaging solutions.

- Reduces plastic usage by offering biodegradable alternatives.

5. Versatility Across Industries

- Used for packaging high-end electronics, luxury cosmetics, fashion accessories, gourmet food, and more.

- Provides a high perceived value that enhances customer satisfaction.

- Suitable for retail display and direct-to-consumer shipments.

Comparing Rigid Box Makers and Corrugated Cardboard Manufacturers

While both a Rigid Box Maker and a Corrugated Cardboard Manufacturer are essential in the packaging industry, they serve different purposes. Here’s how they compare:

1. Material & Structure

- Rigid Boxes: Made from thick paperboard, ensuring a firm and luxurious feel.

- Corrugated Boxes: Made from multiple layers of paperboard, providing cushioning and strength for shipping.

2. Purpose & Applications

- Rigid Box Maker: Focuses on premium packaging for luxury items.

- Corrugated Cardboard Manufacturer: Produces durable boxes for e-commerce, shipping, and industrial use.

3. Customization & Branding

- Rigid Boxes: Offer superior printing techniques, embellishments, and premium textures.

- Corrugated Boxes: Primarily focus on cost-effective printing and bulk manufacturing.

4. Sustainability & Eco-Friendliness

- Rigid Box Makers integrate recyclable paperboard and sustainable wrapping materials.

- Corrugated Cardboard Manufacturers use biodegradable materials and recyclable kraft paper.

Customization Options for Rigid Boxes

A Rigid Box Maker provides numerous customization options to ensure the perfect packaging solution for businesses.

1. Printing Techniques

- Offset Printing: Ensures vibrant and high-definition colors.

- Screen Printing: Used for simple and bold designs.

- Digital Printing: Ideal for short-run custom orders.

2. Special Features

- Foil Stamping: Adds metallic effects for a premium look.

- Embossing & Debossing: Creates a raised or recessed texture on logos and designs.

- UV Spot Coating: Enhances visual contrast with a glossy finish.

3. Box Closures & Inserts

- Magnetic Closures: Enhances user experience with a sleek design.

- Die-Cut Foam Inserts: Custom-shaped for added product protection.

- Corrugated Inserts: Supplied by a Corrugated Cardboard Manufacturer to provide cushioning.

How to Choose the Right Rigid Box Maker

Selecting a reliable Rigid Box Maker ensures high-quality packaging tailored to your brand’s needs. Here are key factors to consider:

1. Experience & Reputation

- Check reviews and portfolio to assess quality.

- Look for industry certifications and client testimonials.

2. Material Quality & Sustainability

- Ensure they offer eco-friendly materials and sustainable practices.

- Partner with a Corrugated Cardboard Manufacturer for complementary packaging solutions.

3. Customization Capabilities

- Choose a provider with advanced printing, finishing, and structural design options.

- Request samples to evaluate the material and print quality.

4. Production Capacity & Lead Time

- Assess their ability to handle bulk orders efficiently.

- Check turnaround times and delivery reliability.

Conclusion

A Rigid Box Maker plays a vital role in enhancing product presentation and protection through high-end packaging solutions. With premium finishes, custom branding options, and superior durability, rigid boxes add immense value to various industries. Compared to a Corrugated Cardboard Manufacturer, which focuses on large-scale shipping solutions, a Rigid Box Maker specializes in luxury and specialty packaging.

By choosing the right Rigid Box Maker, businesses can elevate their brand identity, improve customer experience, and adopt sustainable packaging solutions that align with modern consumer demands.