The automated riveting machine is revolutionising production across industries by improving efficiency, precision, and reliability. Expert Technologies Group, a leader in manufacturing solutions, offers advanced riveting systems tailored to diverse industrial needs. In this article, we explore the applications and benefits of automated riveting technology and its impact on modern manufacturing.

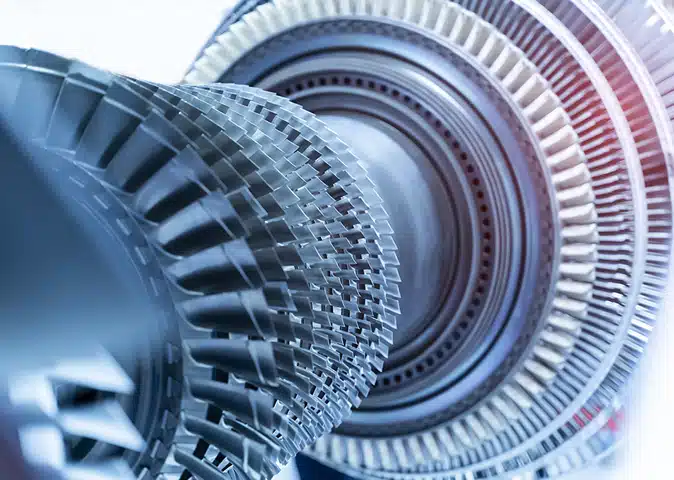

What is an Automated Riveting Machine?

An automated riveting machine is a specialised device that secures components together using rivets without the need for continuous manual operation. This technology streamlines production by ensuring accuracy and uniformity in fastening. It eliminates inconsistencies common in manual processes, making it indispensable for industries requiring high production volumes and consistent quality.

Applications of Riveting Machine Use Across Industries

Riveting machine use spans various sectors, including automotive, aerospace, electronics, and construction. Its ability to create durable, reliable joints makes it essential for industries that prioritise safety and performance.

- Automotive Industry: Used to join car body panels, seats, and interiors, the machine ensures long-lasting, secure fastening for vehicle components.

- Aerospace Sector: In aircraft production, where safety is paramount, riveting plays a key role in maintaining structural integrity.

- Electronics: The machine helps secure delicate components within devices like laptops, mobile phones, and appliances.

- Construction and Infrastructure: From metal bridges to modern building facades, the machine ensures robust fastening in large-scale construction projects.

Advantages of the Automated Riveting Machine

1. Increased Productivity

The automated riveting machine accelerates production by performing fastening operations faster than manual processes, allowing manufacturers to meet high-demand targets efficiently.

2. Precision and Consistency

By automating the riveting process, companies can achieve flawless and repeatable results, ensuring each product meets quality standards.

3. Lower Labour Costs

The machine reduces reliance on manual labour, allowing companies to allocate their workforce more efficiently and focus on higher-value tasks.

4. Enhanced Safety

Automation minimises human interaction with machinery, reducing the risk of workplace accidents and ensuring a safer environment.

5. Flexibility and Customisation

Modern machines are highly adaptable, capable of handling different types of rivets and materials, making them suitable for diverse production needs.

Industrial Riveting Machine: Essential for Large-Scale Operations

The industrial riveting machine is designed to withstand the rigours of high-volume production. These heavy-duty machines offer durability, speed, and precision, making them ideal for industries such as automotive, aerospace, and construction. Expert Technologies Group provides custom solutions, ensuring that businesses have access to the right machine for their specific operational requirements.

Innovations in Riveting Technology

Recent advancements have made the automated riveting machine even more valuable to manufacturers:

- IoT Capabilities: Machines equipped with sensors provide real-time monitoring, ensuring quality control throughout the production process.

- Robotic Integration: The ability to work with robotic systems enables fully automated production lines, maximising efficiency.

- Energy-Efficient Designs: Newer machines are designed with sustainability in mind, reducing operational costs and environmental impact.

Why Choose Expert Technologies Group?

Expert Technologies Group stands out for its ability to provide reliable and innovative riveting solutions. With a focus on meeting the specific needs of each client, they offer cutting-edge automated and industrial riveting machines backed by robust technical support.

Benefits of partnering with Expert Technologies Group include:

- Customised Solutions: Machines designed to align with individual production goals.

- Technical Expertise: Comprehensive support and maintenance services.

- Access to Advanced Technology: State-of-the-art innovations that enhance manufacturing processes.

Conclusion

The automated riveting machine has become a cornerstone of modern manufacturing, ensuring speed, precision, and safety in production. Whether in automotive, aerospace, electronics, or construction, the use of riveting machines ensures reliable fastening for critical applications.

With Expert Technologies Group leading the way, businesses can leverage the advantages of advanced riveting systems to stay competitive and meet the demands of an evolving market. Investing in automated solutions not only improves productivity but also ensures consistent quality, helping companies excel in today’s fast-paced manufacturing environment.