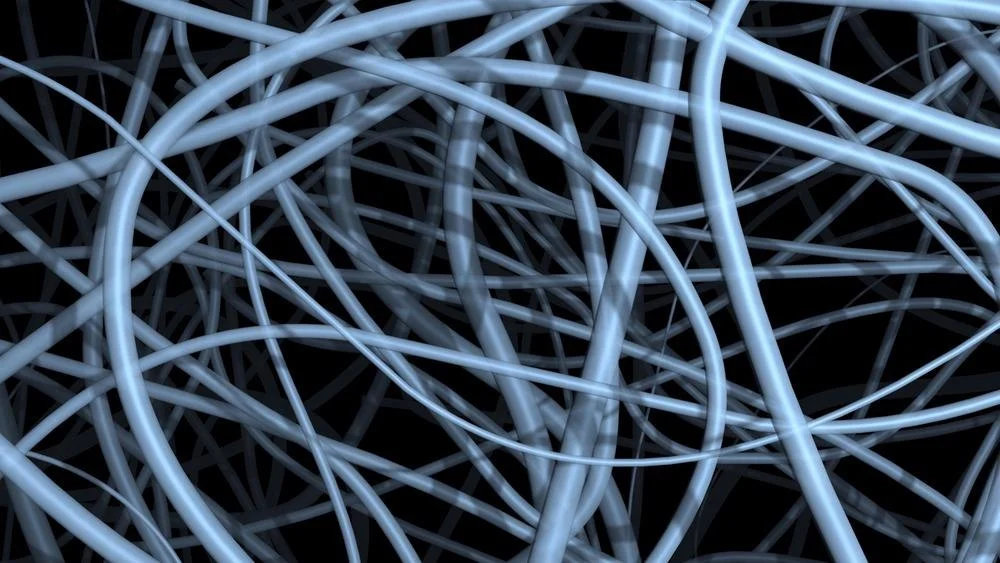

Nanofiber technology has gained significant attention in recent years for its potential applications in fields ranging from healthcare to energy storage. The unique properties of nanofibers, such as their large surface area, flexibility, and high mechanical strength, make them ideal for a wide range of uses. However, the economics of nanofiber production, particularly regarding cost and scalability, presents both challenges and opportunities for manufacturers, investors, and industries looking to adopt this technology. This blog delves into the cost structure of nanofiber production, the scalability of the technology, and the strategies that can help lower costs while increasing production capacity.

Understanding Nanofibers and Their Applications

Nanofibers are fibers with diameters typically ranging from 1 to 100 nanometers. Their nanoscale structure gives them unique physical, chemical, and mechanical properties, making them ideal for use in a wide array of industries. Some of the most common applications of nanofibers include:

- Medical Applications: Nanofibers are used in wound dressings, drug delivery systems, and tissue engineering due to their ability to mimic the extracellular matrix and facilitate cell growth.

- Filtration: Nanofibers have been extensively used in air and water filtration systems because of their high surface area and porosity, which enable them to capture even the smallest particles.

- Energy Storage: Nanofibers are utilized in the production of batteries and supercapacitors, where they improve the efficiency and longevity of energy storage systems.

- Textiles and Fabrics: Nanofibers are increasingly used in advanced textiles for protective clothing, sportswear, and functional fabrics with properties like water resistance, breathability, and antibacterial characteristics.

While nanofibers hold immense potential, producing them at scale and at a competitive price point has been one of the most significant barriers to widespread commercialization.

Cost Structure of Nanofiber Production

The production of nanofibers involves several stages, each contributing to the overall cost. The primary factors that determine the cost of nanofiber production include:

- Raw Materials:

- The choice of materials significantly impacts the cost of production. Common materials for nanofiber production include polymers such as polyvinyl alcohol (PVA), polycaprolactone (PCL), and cellulose acetate. High-performance materials like carbon, ceramics, and metallic nanofibers are more expensive and can drive up costs. Moreover, specialized additives or functional coatings for specific applications also contribute to material costs.

- Production Techniques:

- Electrospinning: This is the most widely used method for producing nanofibers due to its simplicity and ability to produce fibers with controlled diameter and morphology. However, it remains a labor-intensive process with relatively low production rates, making it costly for mass production.

- Melt Spinning: Melt spinning is another technique used to produce nanofibers, but it requires high temperatures and more energy, increasing operational costs. Nonetheless, it is considered more scalable than electrospinning.

- Forcespinning and Centrifugal Spinning: These methods are newer and offer faster production rates than electrospinning. While they are more cost-effective, they are still in the developmental stage and not widely adopted.

- Energy Consumption:

- Nanofiber production can be energy-intensive, particularly when using techniques such as melt spinning that require high temperatures. The energy costs contribute significantly to the total production cost, especially when scaled up.

- Labor and Expertise:

- Due to the complexity of nanofiber production techniques, highly skilled labor is often required. This expertise comes at a premium, increasing operational costs.

- Post-Processing and Functionalization:

- Depending on the intended application, nanofibers often require additional processing such as functionalization, coating, or sterilization. These additional steps not only increase the time required for production but also add to the overall cost.

Scalability Challenges

Scalability is one of the main challenges in nanofiber production. While small-scale production for research and development purposes is feasible and relatively well-established, scaling up to commercial production is more complex. Some of the key scalability challenges include:

- Production Throughput:

- Current nanofiber production techniques, especially electrospinning, have low throughput. This is due to the time it takes to produce the fine, uniform fibers required for high-performance applications. Electrospinning can produce high-quality fibers, but at a rate that is far too slow for most industrial applications, making large-scale production costly and time-consuming.

- Consistency in Quality:

- When scaling up, maintaining the uniformity and quality of nanofibers becomes difficult. Nanofiber properties such as diameter, strength, and porosity must be carefully controlled to meet the specifications required for various applications. Inconsistencies can lead to a higher rate of defects, reducing overall productivity and increasing waste.

- Equipment and Infrastructure Costs:

- Specialized equipment is required for large-scale nanofiber production, and this machinery can be expensive. Additionally, scaling up production often requires significant investment in infrastructure, such as larger production facilities, more advanced control systems, and higher energy inputs.

- Regulatory Hurdles:

- For applications in healthcare, filtration, and food packaging, regulatory approval can be a lengthy and expensive process. Manufacturers need to ensure that their production processes meet stringent regulatory standards, which can add to both the cost and time needed to scale up production.

Strategies for Reducing Costs and Increasing Scalability

Several strategies can be employed to overcome the cost and scalability challenges associated with nanofiber production:

- Automation and Advanced Manufacturing:

- Automation of nanofiber production processes, such as electrospinning, can help reduce labor costs and increase production rates. Using robotic systems or advanced control algorithms can streamline production, leading to more consistent quality and fewer defects.

- Alternative Production Methods:

- Exploring alternative production techniques like forcespinning or centrifugal spinning, which offer higher throughput, can help reduce costs and improve scalability. These methods are also more energy-efficient, contributing to lower operational costs.

- Economies of Scale:

- As with most manufacturing processes, scaling up can lead to economies of scale, where the cost per unit decreases as production increases. Larger facilities and investments in more efficient equipment can help drive down costs as production volumes grow.

- Collaboration and Partnerships:

- Collaborative efforts between research institutions, manufacturers, and governments can help accelerate the development of cost-effective production techniques. Public-private partnerships, in particular, can reduce the financial burden of scaling up by sharing costs and expertise.

Conclusion

The economics of nanofiber production are shaped by the high cost of raw materials, energy consumption, labor, and post-processing. Scalability remains a critical challenge, but ongoing advancements in production techniques, automation, and collaboration between industries offer promising solutions. With strategic investment and technological innovation, nanofibers could transition from niche applications to widespread commercial use, unlocking their potential in various industries. While initial costs may be high, the long-term benefits of reduced production costs and increased scalability could position nanofibers as a cornerstone of future technological advancements